The Function of Vacuum Electrical Interfaces in High-Tech Fields

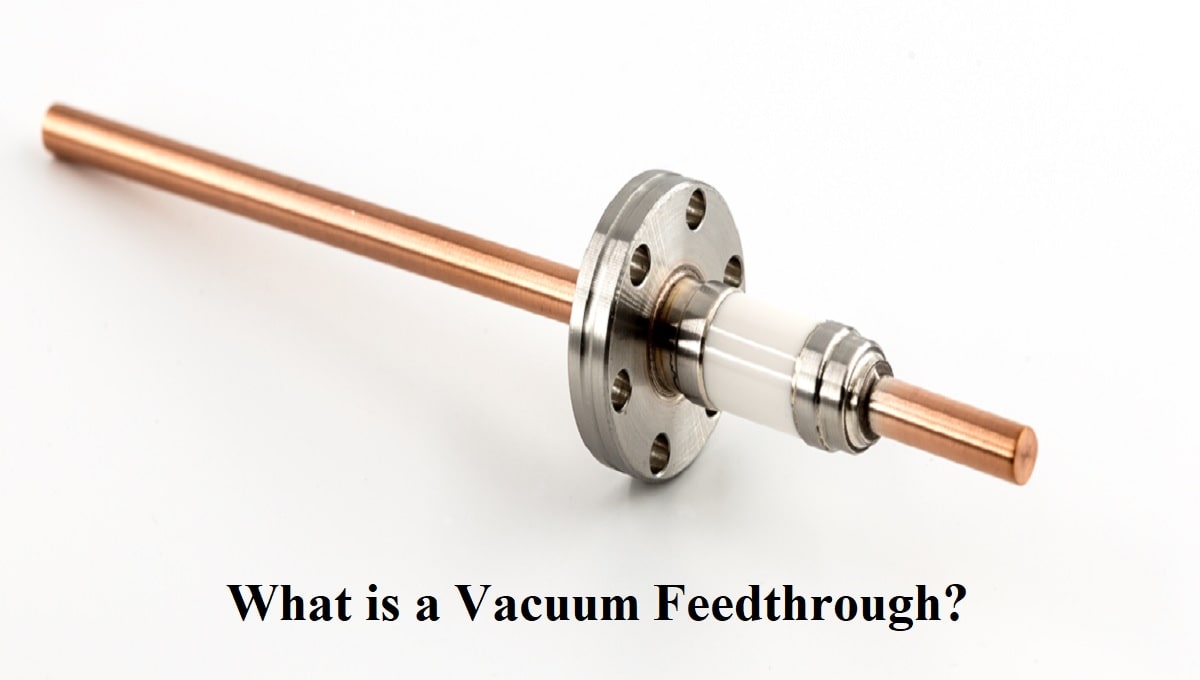

In a rapidly advancing landscape within high-tech sectors, maintaining accuracy and efficiency are paramount. One frequently overlooked element that plays a crucial role for achieving these standards is the vacuum electrical feedthrough. These specialized devices enable the seamless transmission of electrical signals between the outside environment with equipment operating within a vacuum. This capability proves to be essential for various applications, ranging across semiconductor manufacturing and scientific research, where maintaining a controlled atmosphere is vital for optimal performance.

Vacuum feedthroughs designed for provide a reliable connection while preventing gas leakage as well as contamination within the vacuum chamber. They ensure that high-voltage or low-voltage electrical signals may be safely routed; this allows complex systems for function effectively. The significance of these components stands underscored by their diverse applications such as particle accelerators , vacuum furnaces , and cleanroom environments. Understanding these mechanics and applications pertaining to vacuum electrical feedthroughs not only highlights their importance in high-tech industries but also illustrates the intricate balance of engineering which supports modern technological advancements.

Grasping Vacuum Electrical Connection Systems

Pressure electrical signal connection systems are vital components employed to transmit electrical signals into a vacuum environment. These components are constructed to ensure the purity of the sealed environment while allowing electrical interconnection, which is crucial in various high-tech applications. Whether in scientific research, semiconductor fabrication, or space innovation, these systems enable the functionality of devices that operates within low-pressure conditions.

These feedthroughs typically are made of conductor materials that are isolated from the vacuum chamber. The insulation is necessary to stop electrical leakage between the internal sealed space and the external atmosphere. Various configurations and materials are applied based on the exact requirements of the use, including temperature tolerance, electrical specifications, and mechanical stability.

The engineering and production of these feedthroughs also consider elements such as thermal transfer and durability to outgassing. As progress in technology advance, innovations in feedthrough design play a crucial role in enhancing performance, reliability, and safety in high-tech industries where vacuum conditions are vital for best operation.

Uses in High-Tech Sectors

Vacuum feedthroughs play a crucial role in various advanced technology industries, particularly in the fields of semiconductor manufacturing and research laboratories. In semiconductor fabrication, these components facilitate the exact delivery of electrical signals into high-vacuum environments, essential for the functioning of equipment such as reactors and thin film deposition systems. By maintaining the integrity of the vacuum while allowing for electric connections, they enable the creation of microelectronics with high reliability and performance.

Another significant application is in the realm of particle accelerators and synchrotrons. These installations require numerous feeds to manage the complex systems of power, signal processing, and control within a vacuum. These feedthroughs are essential for ensuring that sensitive electronics operate properly while minimizing disruption from outside EM environments. This integration is key for achieving the scientific goals of these institutions, such as materials research and medical research.

Moreover, these components are more used in the area of aerospace technology. Satellites and space probes operate in a vacuum and require strong electrical links for various instruments and communication systems. Feedthroughs designed for harsh conditions ensure reliability over time and efficacy, which are crucial for missions that may last several years. Their application in space underscores the significance of these devices in enabling state-of-the-art innovations and deep-space exploration.

Benefits and Issues

Vacuum feedthroughs offer several major advantages that make them vital in high-tech industries. One of the primary advantages is their ability to provide dependable electrical connections in vacuum environments. This ensures maximum performance in uses such as particle accelerators, semiconductor manufacturing, and vacuum chambers, where maintaining a vacuum is crucial for reducing contamination and maximizing operational efficiency. Additionally, vacuum feedthroughs can withstand extreme conditions, including high temperatures and radiation, making them suitable for challenging environments.

Despite their benefits, there are issues associated with vacuum electrical feedthroughs. The manufacturing process can be complicated and requires precision engineering to ensure that the feedthroughs maintain a hermetic seal. Any flaws during production can lead to failures that compromise the integrity of the vacuum system. Furthermore, the fitting and handling of these components require specialized knowledge and care, as any carelessness can lead to harm or failure in the vacuum setup.

Another issue is the financial considerations of utilizing vacuum feedthroughs. High-quality materials and advanced manufacturing techniques add to a higher price point compared to standard electrical connectors. This can be a challenge for some companies, particularly smaller enterprises or those with tight budgets. However, the sustained benefits of increased reliability and performance often outweigh the initial investment, making vacuum electrical feedthroughs a worthwhile consideration for businesses operating in high-tech industries.